Rock Mechanic Analysis for Crown Pillar Extraction at Tara

Project Description

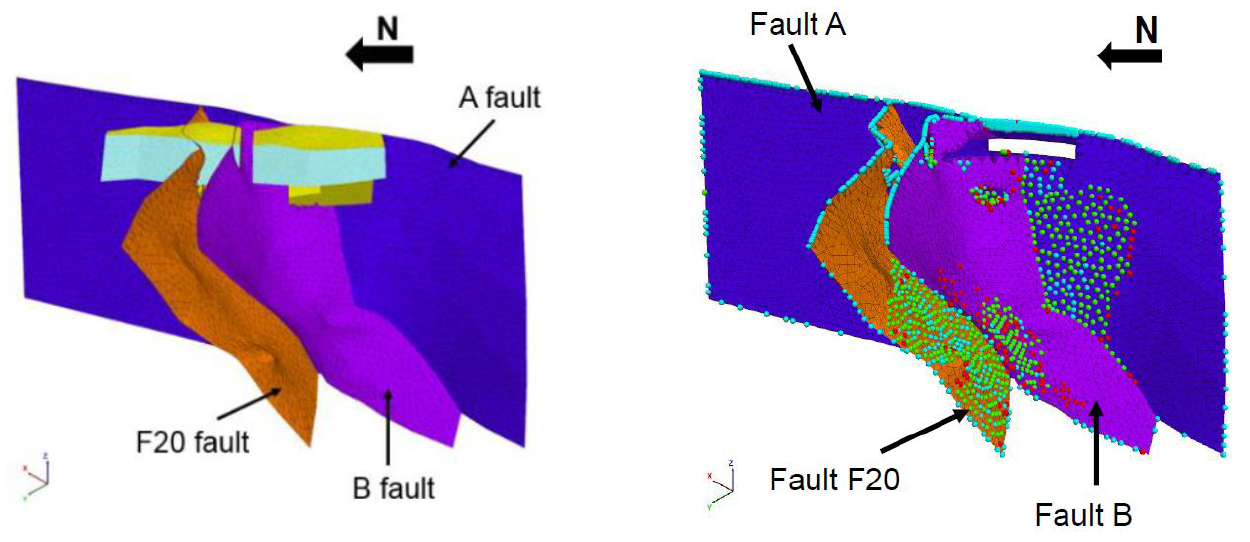

Boliden Tara Mines is Europe’s largest zinc mine, with an annual production of 2.6 million tones of ore, and has been in operation since 1977. This project was part of the required planning application to the authorities regarding crown pillar extraction in the norther portion of Boliden Tara Mines. It was conducted in two phases – first a continuum model was analyzed in FLAC3D, which was then followed by a discontinuum modelling in 3DEC with included faults. Both of them were run with the aim of assessing the rock mechanical conditions and consequences of mining the crown pillar, with particular focus on the surface impact, in addition to determining the influence of the existing faults on the crown pillar extraction.

Itasca's Role

Itasca’s task was to assess the rock mechanical effects of mining the crown pillar and compare the obtained results between continuum and discontinuum models in order to evaluate the significance of the included faults. The models were built with high geometrical details using the CAD-software Rhino together with the mesh generator Griddle. The continuum model consisted of planned crown pillar stopes, geological structures, and all the existing stopes. Later on, the discontinuum model was supplemented with faults and the mined out stopes were limited only to the ones that proved to have an impact on the crown pillar behavior. Extraction of the crown pillar was done stepwise with one stope being mined at any one time in FLAC3D, while in 3DEC extraction was simulated in two mining steps with subsequent backfilling. Scenarios with different crown pillar stopes heights and widths were simulated and compared.

Project Results

All analyzed cases proved to be numerically stable, implying that the overall stability of the remaining crown pillar and excavated stopes is satisfactory even for large stope heights. Ground surface deformations above the area of interest were negligible as well as the displacements and shear stresses along the faults. Changes of the crown pillar stopes dimensions are of no visible consequences on the faults and vice versa. Nevertheless, a cautious mining sequence, excavating only one, or few stopes at the same time, is recommended to minimize the slip along the faults. Moreover, ground support with bolts, shotcrete, and cables, are required to support the low-stress/tensile zones around the crown pillar stopes.

Project Image(s)