Machine Learning Tool for Rapid Crane Bearing Capacity Prediction

PROJECT DESCRIPTION

A new wind turbine is being installed in the United States every 2.5 hours, and the industry is projected to grow 400% by 20501. Wind farm construction requires large cranes to lift massive wind turbine structures over 300 feet tall and exceeding 160 tons, and the industry trend is for increasingly large wind turbines. Installing these structures requires many crane “walks”, moving the heavy cranes around 50 miles along soil surfaces of varying strengths. Moving the cranes quickly is critical to installation economics, but this must be done safely by ensuring soil strength stability to avoid sinking or toppling the crane. Conventional best practices require cone penetrometer tests (CPTs) and performing numerical modeling to establish a safe path for moving the cranes. However, the turnaround time for these analyses is on the order of four to six weeks.

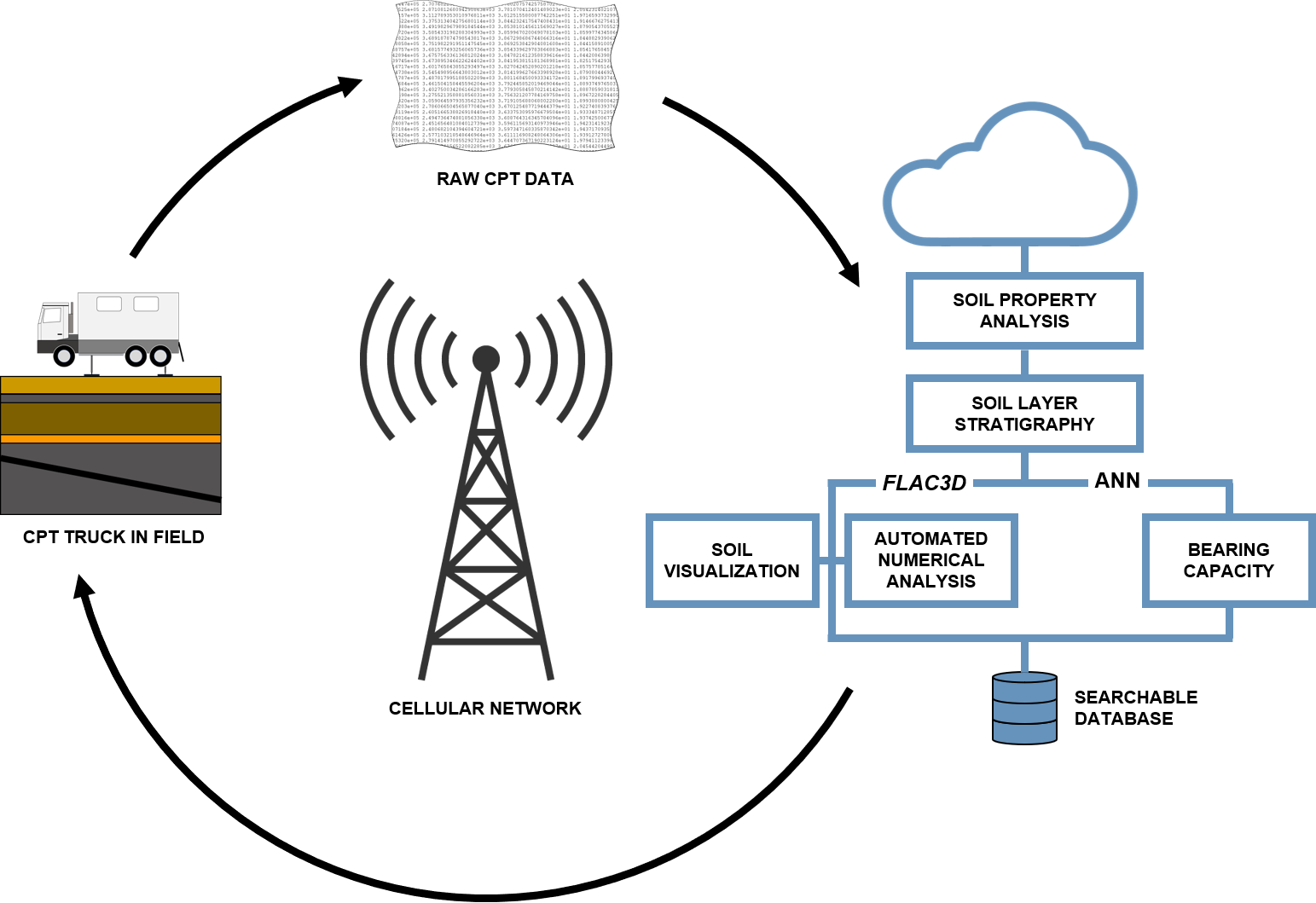

Mortenson partnered with Itasca to develop a rapid bearing capacity prediction tool using Python programs, FLAC3D, and machine learning.

ITASCA'S ROLE

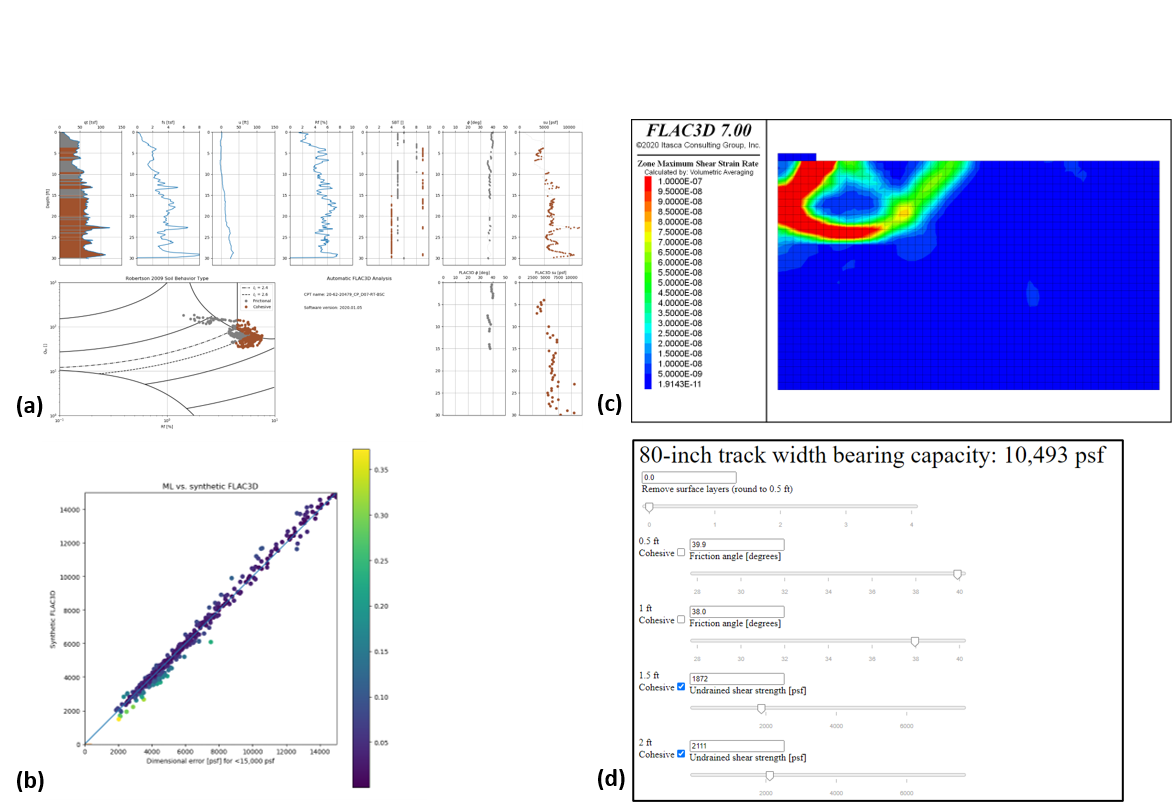

Itasca has greatly reduced the time and numerical modeling expertise needed to predict soil bearing capacity, vital for crane walk planning, from weeks to minutes. Conventional best practices for soil stability analysis rely heavily on manual assessment of soil information. Itasca’s approach centered on two tasks. First, a set of custom Python programs were developed that automate the CPT field data import, soil classification, and soil property estimation. Itasca then fully automated the FLAC3D modeling process for crane bearing capacity and developed automated algorithms for interpreting the loads that produced bearing capacity failure. Next, Itasca developed a web-based tool implementing an artificial neural network (ANN) model trained from a large dataset of synthetic data (generated from FLAC3D models), validated using field data, and extended to a wide range of crane track sizes using a scaling approach. As part of the ANN training, Itasca developed an innovative method to reduce training data requirements. The web-based tool provides very accurate, near real-time predictions of preliminary soil stability analysis, to determine where additional testing may be required, that would otherwise require thousands of hours of computing time.

PROJECT RESULTS

The web-based tool developed can reproduce results of the FLAC3D bearing capacity modeling with very high accuracy (over 99%) and provide near real-time predictions three or four orders of magnitude faster than the conventional best practice. From the field, this tool allows uploading CPT data to be processed in the cloud for prediction of the soil bearing capacity, automated FLAC3D numerical modeling (for validation), and soil property visualizations for QA/QC purposes. Instant onsite feedback is available using the Explore Tool app where users can adjust the layer properties (and remove a variable amount of soil from the top of the stratigraphy) and predict the bearing capacity. The following are the main results of this project:

- Substantially improved crane walk safety and mitigation of equipment damage.

- Reduced time and numerical modeling expertise needed to predict soil bearing capacity, accelerating project schedules.

- Near real-time feedback on the soil bearing capacity at a test location, allowing enhanced crane walk planning and reducing or eliminating the need for multiple rounds of soil investigations.

Mortenson Construction and a partner geotechnical consulting firm are using Itasca’s web-based tool for crane walk planning in wind turbine projects in Minnesota and throughout the United States.

REFERENCES

1USDOE (2021). Map: Projected Growth of the Wind Industry From Now Until 2050.

2Photograph courtesy of Mortenson Construction.