Hongping Pumped Storage Power Station Stability Analysis

Project Description

Pumped storage involves large, reversible water energy systems utilizing the potential energy of water to store and generate electricity. Hongping Pumped Storage Power Station is located in northwest Jiangxi Province, China, and will be developed in two phases. Once complete, the power station will have a capacity of 3,000 MW. As part of the feasibility study, this analysis is mainly for the underground powerhouse cavern group of the second phase of the project.

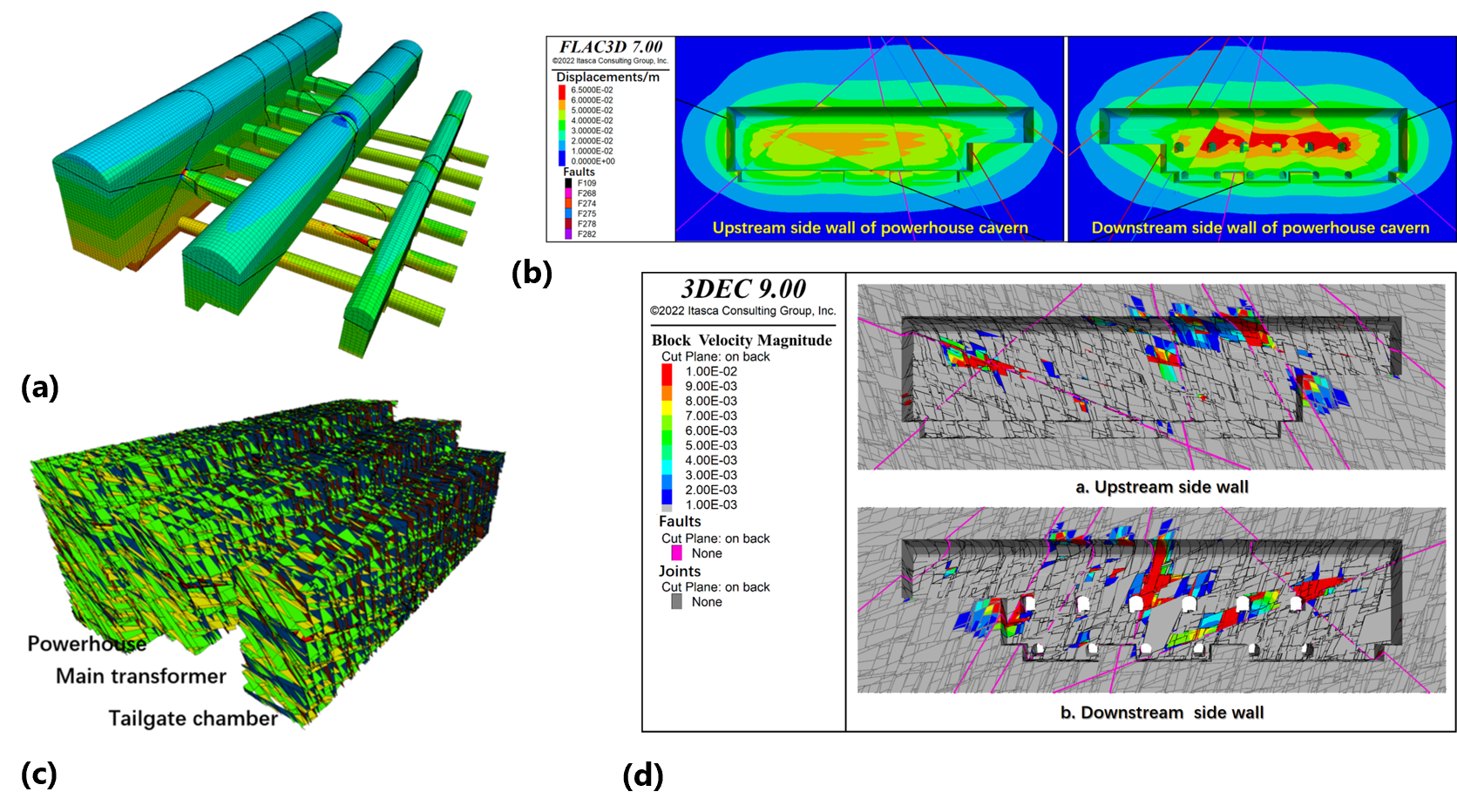

The underground powerhouse cavern group is up to 520 m deep and is mainly composed of the powerhouse cavern, the main transformer cavern, and the tailgate chamber. Cavern size ranges from 194–230 m long, 8–24.5 m wide, and 20.6–56.3 m high. The cavern group resides mainly in a Class III rock mass in good-quality sandstone. Six major faults and four joint sets have been observed in the field.

ITASCA's Role

ITASCA was tasked to study: 1) the rationality of the cavern layout of the underground powerhouse; 2) the stability analysis and support design of the surrounding rock of the cavern group of the underground powerhouse; and 3) the control of block stability by the discontinuities of the cavern group. ITASCA constructed FLAC3D models that included the major faults and 3DEC models that included the major faults plus the four joint sets. Griddle was used to simultaneously generate both FLAC3D and 3DEC models. The 3DEC models were used primarily to identify the location and size of potential unstable blocks around the underground caverns using the strength reduction method (SRM) for fault and joint strength properties. In accordance with Chinese industrial standards, the Mohr-Coulomb constitutive model was used to simulate the mechanical behavior of the rock mass with parameters provided by site geological engineers.

Project Results

FLAC3D modeling results indicated that the risk of stress-induced damage may not be a critical concern in this project. Maximum displacements are predicted to be up to 78 mm and occur along the downstream side-wall of the powerhouse cavern, near Fault f275. After implementing a shotcrete liner and rockbolt support, deformations are reduced by 1–4%, while the area cut by the fault is reduced by about 7–8%. The axial stress of rockbolts near the large fault will exceed the design capacity of 400 MPa. When the strength of faults and joints was reduced by a factor of 1.5 in 3DEC, some rock blocks exhibited instability, indicating these areas needed additional reinforcement.

References

HydroChina ITASCA R&D Center (2022). Stability Analysis of Rockmass of Underground Powerhouse Cavern Group for HongPing Pumped Storage Power Station Project. Report to HDEC, HIC_HP_ 01/2022 (Oct).