Modeling Blast-induced Vibrations to Limit Damage to Underground Stopes

Project Description

Itasca Consulting Group was recently hired by Hindustan Zinc to model blast-induced vibrations at the Rampura Agucha Mine in India. Concurrent open-pit mining and sub-level open stoping are currently under way at Rampura Agucha. The goal of the work was to gain insight into how blasts should be designed to better protect underground excavations. Current operational guidelines use the empirical scaled distance formula to calculate safe distances from surface blasts of a given size to the nearest underground workings. The scaled distance analysis assumes the charge to be a point mass, the wave propagation path is assumed to be a straight line, and the rock is taken as homogeneous and continuous.

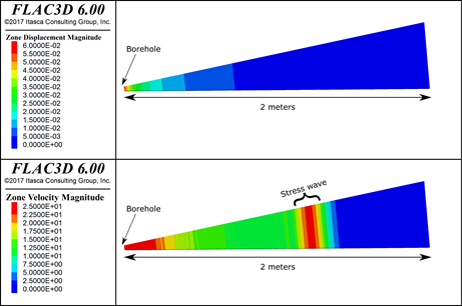

Itasca has developed a numerical modeling methodology that overcomes these limitations and complements the scaled distance analysis. Two FLAC3D models are used to link the small-scale detonation and crushing behavior to the mine-scale stress wave propagation behavior.

Itasca's Role

A small-scale FLAC3D model represents an annulus of rock 4 m in diameter with the explosive in the center. The gas pressure resulting from the detonation is applied to the borehole surface. As the borehole deforms, the applied gas pressure is reduced according to the gas equation of state. This model accounts for both elastic and plastic deformation in the rock and the energy quantities associated with stress wave propagation. Before the stress waves reach the outer boundary of the model, the energy in the stress waves is measured. This energy is converted into an equivalent strain energy (isotropic stress) in a single 1 meter cube element of the mine-scale model. The energy is transferred to the mine-scale model by setting the isotropic stress of elements at the time of local detonation. In this way, only the explosive energy that escapes the borehole area as a stress wave is present in the mine-scale model.

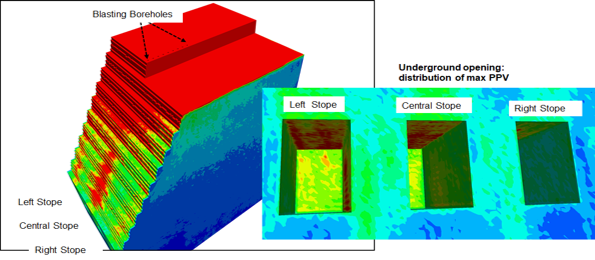

A mine-scale FLAC3D model represents a section of the open pit with a cubic mesh of 1 meter elements. Underground excavations are included in the model. The FLAC3D elastic and damping properties are calibrated by comparison with peak particle velocity (PPV) vs distance measurements made at the mine. PPV is plotted on the excavation surfaces and scatter plots of PPV vs distance are shown for every gridpoint in the FLAC3D model. Blasts that are closer to the underground excavations show a stronger geometric effect of local wave amplification on the excavation surfaces.

Project Results

The numerical analysis confirmed that the current blast designs limit the PPV to below a critical value. A proposed design change of including gravel decking was shown not to have a large effect on the induced vibrations. The modeling showed the importance of changing the blast design as the distance between the explosive and the stope decreases.