Mine-Scale Model for Caving and Ground Deformation Prediction

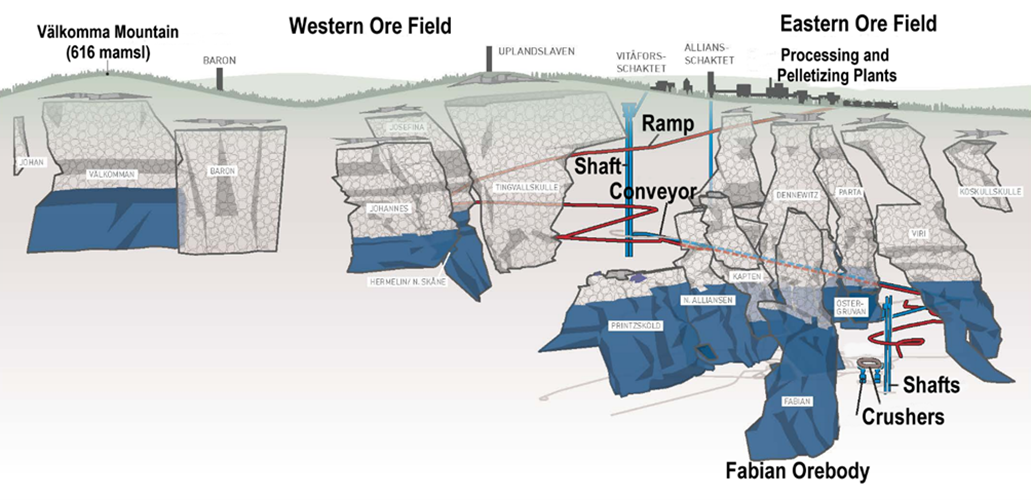

The Malmberget iron ore mine is a large-scale sublevel caving (SLC) mine in northern Sweden, owned and operated by the Luossavaara-Kiirunavaara Aktiebolag (LKAB) mining company. The mine comprises 20 orebodies of varying size, shape, and orientation over an area of 8 km2. The total annual production currently amounts to 16 million metric tons of iron ore, with the deepest extraction point at approximately 1000 m depth from the ground surface. A coupled CAVESIM-FLAC3D

model was developed to simulate production and material flow around all the orebodies in Malmberget, as well as the rock mass response outside the caved volumes. The model was used to predict ground surface caving and deformations induced by cave mining, as well as the influence on critical infrastructure underground.

Project Overview

Large-scale sublevel cave mining (SLC) remains the mining method of choice for efficient underground mining in the Malmberget iron ore mine. However, SLC mining ultimately results in ground deformations above active mining areas, thus necessitating relocation of surface infrastructure and/or residential areas within the areas with large and damaging deformations. Moreover, caving may also affect underground infrastructure, and a prediction methodology for both surface effects and underground infrastructure is warranted.

To address this, a coupled numerical model utilizing FLAC3D (version 7.0) and CAVESIM (version 6.5) was used to simulate material flow and cave propagation, as well as rock mass response outside the caved volumes. Large-scale geological structures were explicitly included in the model, as well as the local geology near the orebodies.

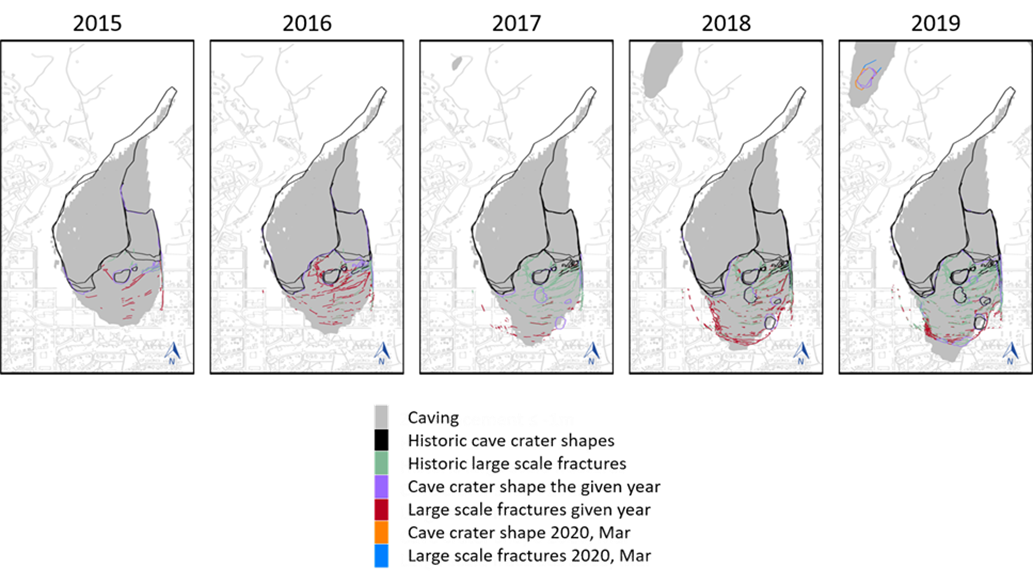

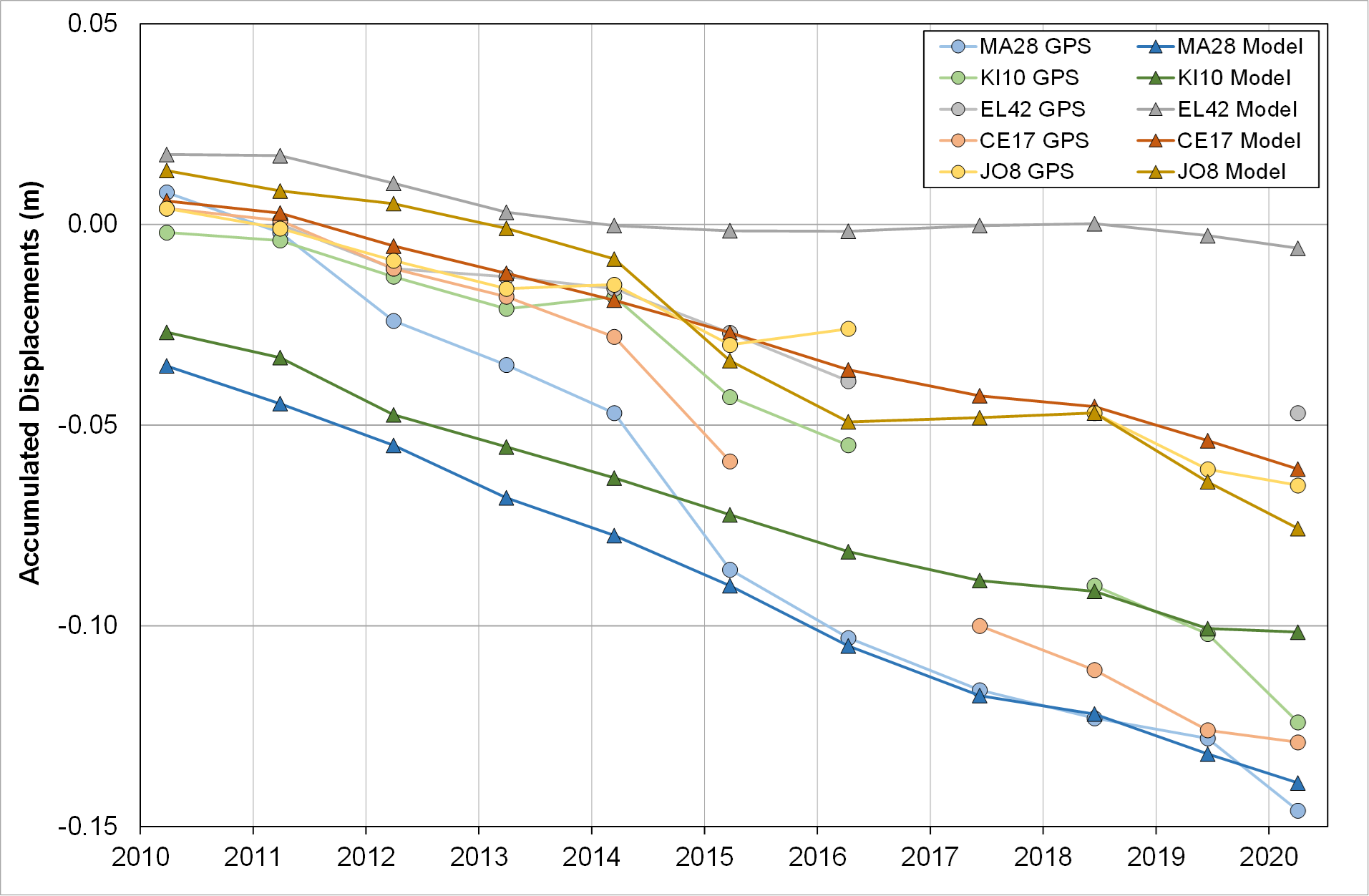

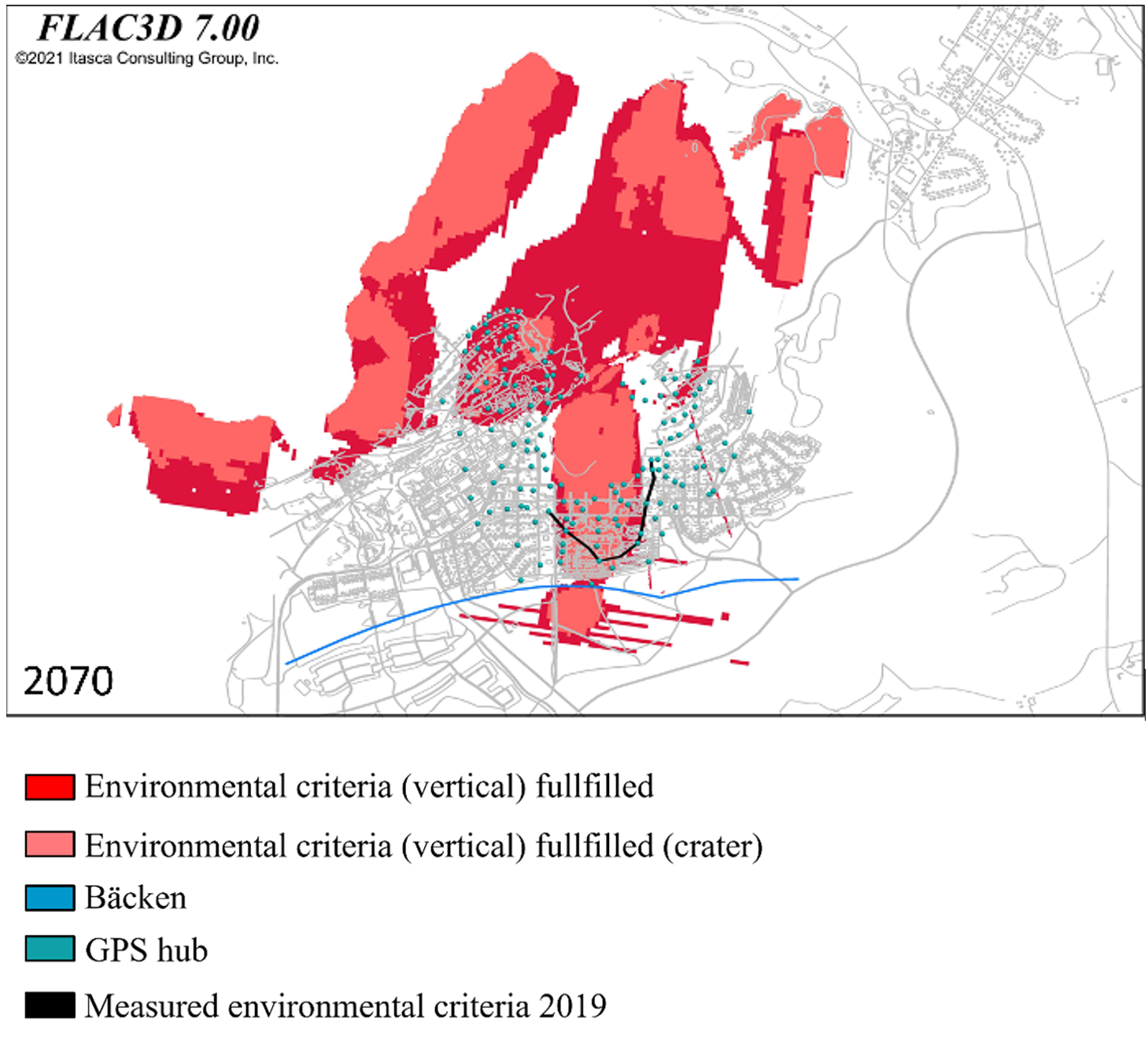

Production was simulated from the start of mining to the present, and the model was calibrated against observed cave cratering on the ground surface and inferred cave shapes from seismic monitoring. Model validation was accomplished through comparison against measured ground surface deformations. The calibrated and validated model was then run for future mining and a planned production increase up until year 2070. The results were evaluated with respect to surface cave cratering, ground surface deformations, and fulfillment of the environmental strain criteria for the mine imposed by the regulators.

CAVESIM-FLAC3D Model

The 3D model includes all orebodies in Malmberget and six large-scale structures that were modeled as continuous discrete planes without any thickness. The FLAC3D model was built using an "oct-tree" mesh in which the mesh is composed of hexahedral zones arranged in a structured cubic pattern. This applies for the whole model except in the area around the large-scale structures, where an irregular hexahedral mesh was built to follow the undulation of the structures. The mesh around the structures was built in the CAD-software Rhino along with the Itasca mesh generator Griddle.

Material draw in CAVESIM was modeled on a ring-by-ring basis. The draw column from each ring interacts with the draw from adjacent rings and previously mobilized material, allowing emergent draw patterns to form inside the cave rock column, which are relayed to FLAC3D as flow rates. The flow rates are then used by FLAC3D to calculate the back pressure from the cave and subsequently the stress redistribution caused by the discontinuous flow.

The combined information from FLAC3D and CAVESIM allows for emergent caving to form based on the draw pattern and the geomechanical properties of the host and rock including airgaps from delayed caving. The emergent cave in turn affects the deformation and stress redistribution patterns around the cave column based on the differential flow rates inside the cave with flowing regions supplying less confinement to the cave boundary than stagnated regions (Hebert and Sharrock, 2018).

Constitutive Model

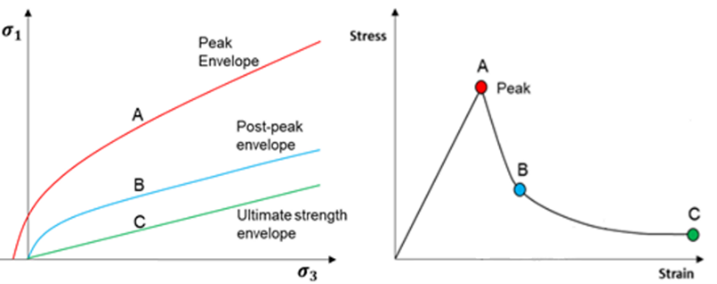

The 3D model used the Itasca constitutive Model for Advanced Strain Softening (IMASS) for all geological entities. Strength weakening in the IMASS constitutive model is defined by three Hoek-Brown strength envelopes: a peak envelope and two residual strength envelopes (Ghazvinian et al., 2020).

The peak behavior is based on the built-in modified Hoek-Brown model. The peak strength envelope parameters are calculated from the classic Hoek-Brown equations based on GSI and intact rock parameters UCS and mi.

The two residual strength envelopes describe the rock mass softening during plastic straining. At the first residual strength envelope (post-peak) the rock mass is assumed to have undergone fracturing, but the resulting rock fragments are still fully interlocked. The second residual strength envelope (ultimate strength) represents the bulked rock mass residual strength with a minimum degree of interlocking. The strain region between the first and second residual envelopes describes the behavior of a cohesionless, perfectly frictional material with progressively decreasing interlocking allowing a realistic strain softening behavior to be modeled.

Results

Model calibration and validation

The model was calibrated against observed cave cratering on the ground surface and inferred cave shapes from seismic monitoring, followed by model validation against measured ground surface vertical deformations. Overall, a good agreement between model output and crater observations was found in the calibrated model, and there was a fair agreement in the ground surface vertical deformations for most monitoring points, with a few exceptions.

Model prediction

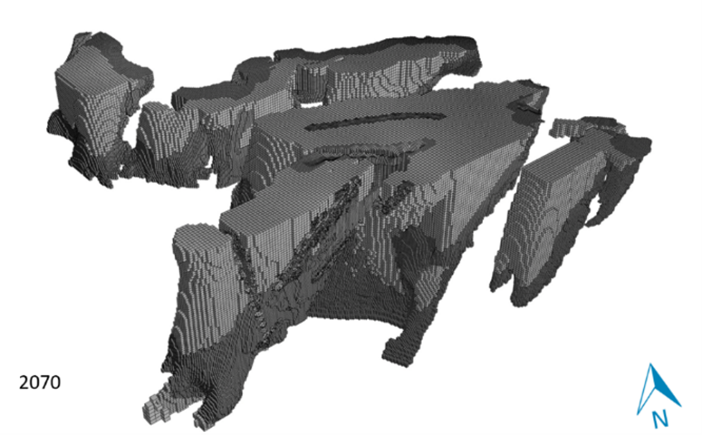

The model was used to predict the volumes of caved rock between the years 2020 and 2070. Results showed that for most of the orebodies, caving is progressive as long as the mining is active, and the caved volumes grow all the way to the ground surface. After the mining in an orebody was terminated, a sharp decrease in the growth of the caving volume was found.

The extent of areas of caved rock and fulfilled environmental criteria was evaluated for each mining step/year in the model. The model results agree very well with the measured values for year 2019. The area with fulfilled environmental criteria was found to increase steadily with future mining.

References

Ghazvinian, E., Garza-Cruz, T., Bouzeran, L., Fuenzalida, M., Cheng, Z., Cancino, C. & Pierce, M. "Theory and Implementation of the Itasca Constitutive Model for Advanced Strain Softening (IMASS)" in R Castro, F Báez & K, Suzuki (eds), Proceedings of the Eighth International Conference & Exhibition on Mass Mining, pp. 451–461, 2020.

Hebert, Y., Sharrock, G. "Three-dimensional simulation of cave initiation, propagation and surface subsidence using a coupled finite difference–cellular automata solution", in Y Potvin & J Jakubec (eds), Proceedings of the Fourth International Symposium on Block and Sublevel Caving, pp. 151–166, Australian Centre for Geomechanics, 2018.