Solution-Mining Modeling (2016)

A confidential mining client was interested in evaluating various potential future solution-mining scenarios using a numerical model in order to assess potential ore recovery, capital costs, and cavern lifetimes, as well as to overall optimize the proposed mine plan. Modeling of solution mining requires that the key processes controlling the mineral dissolution are modeled; however, there are numerous factors that complicate the details of the dissolution process that are impractical or impossible to account for in a model.

Geometry Model for the Follo Line Project (2016)

The Follo Line project is the largest railway project in Norway in modern times. The Follo Line is a high-speed railway partly in tunnel from the traffic hub at Ski to Oslo central station. The project comprise a 20 km long tunnel. The new railway is passing through central Oslo, beneath existing infrastructure which creates challenging conditions due to overlapping tunnels and multiple intersections.

Back-Analysis of Initial Stress at Shallow Depth – A Case Study (2016)

At shallow depth, the initial stress state can significantly affect the behavior of the rock mass around excavations, but stress measurements are usually subjected to high levels of uncertainty. This was the case at the Odenplan railway station in Stockholm where unexpectedly large deformations were measured during the excavation.

Discrete modelling of lime kilns (2016)

KERNEOS Aluminate Technologies wishes to exploit the bauxite fines generated during the extraction, conditioning and transport of bulk bauxite, which are currently unused. To achieve this objective, the PARC project was built around 2 academics and 4 industrial companies, experts in their field.

Numerical modeling of dredged sand filled geotextile tubes behavior under seismic loading (2016)

A nearshore 120m long causeway is planned for the Mozambique LNG TMOF Project. Geosintex S.R.L. proposes a structure composed by synthetic geotubes (see Figure) for protecting the road against erosion. The mechanical behavior of this structure must be understood better. The evaluation of the potential for liquefaction of the road sandy basement and the geotubes filling material is of particular interest.

Regional-Scale Stress Model of the Stockholm Area (2016)

New metro lines are planned in Stockholm, comprising a total length of approximately 20 km with 10 new stations, mostly located underground. One of the new lines will pass under Saltsjön (a bay of the Baltic Sea) and through a major regional large-scale geological structure. The stress magnitudes and orientations around the structure are highly uncertain, and stress measurements are not practically possible near the structure. To quantify possible stress conditions near the structure, discontinuum threedimensional numerical modeling was conducted.

Liquefaction Risk Mitigation using Jet Grouting Cells (2016)

Trevi Group has been involved in the design-build of a commercial building in Turkey in an area prone to liquefaction. The foundation of the building is located approximately 10 m below original grade, which still leaves about 10-12 m of potentially liquefiable sand underneath the bottom slab.

Hopper charging with spherical particles including rolling resistance mechanism (2015)

Evaluate the feasibility of using the distinct‐ element modeling to study the flow and segregation of frictional particles without cohesion.

Simulate an experimental test corresponding to the charge/discharge of a scale model batch hopper.

Analyze the segregation observed in the hopper after its charge.

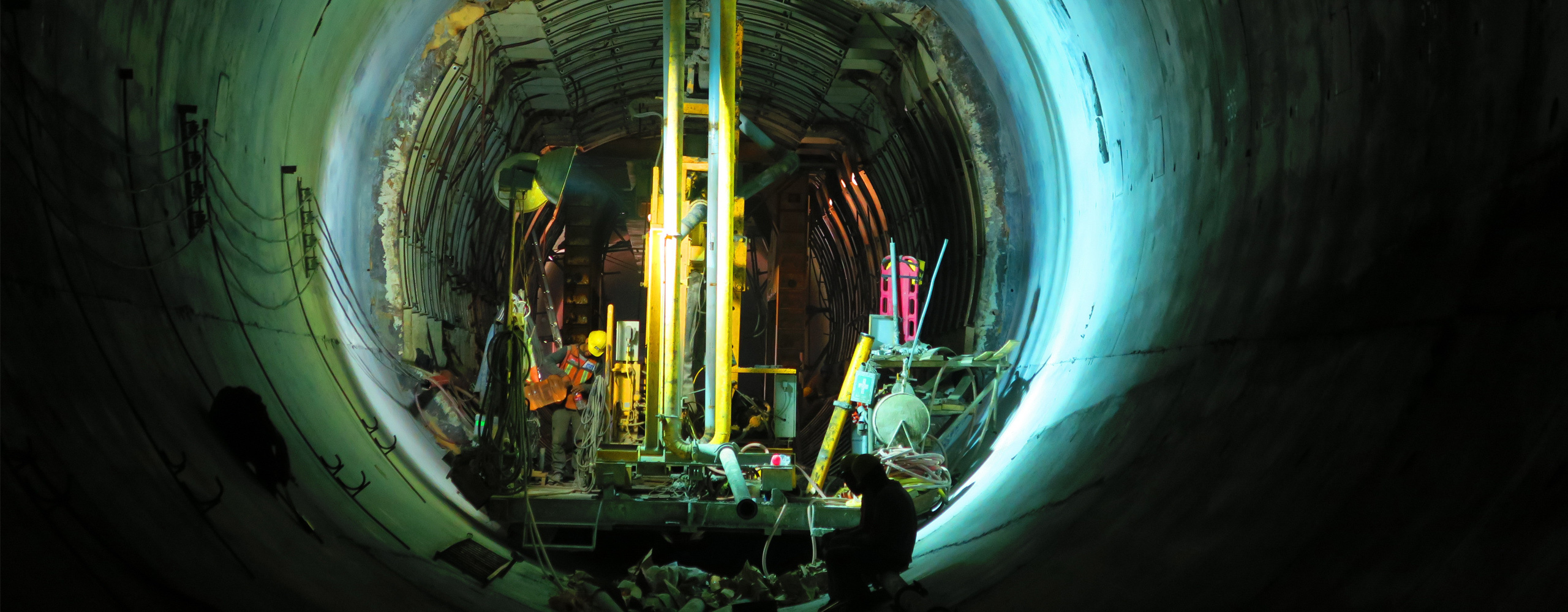

Tunneling in Mixed Face Conditions (2015)

A research project on tunneling in mixed face conditions (rock-soil) was carried out with the aim to increase the knowledge and to better understand deformation mechanisms when these particular conditions arise. A back analysis of a case study involving the tunnel passage under the Maria Magdalena church was performed as a second task of the project, in which soil stratigraphy, rock/soil reinforcement, and extraction sequence were simulated explicitly and in detail.

Guidelines on Design of Rock Excavations (2015)

In 2009, the Swedish National Rail Administration presented a handbook with guidelines for the design of the load-bearing structure of rock tunnels. Following the merging of several transport administrations into The Swedish Transport Administration, an updated version of the handbook was required.

Hopper discharge and flow comparison against experiments (2015)

Evaluate the feasibility of using the distinct‐ element modeling to study the flow and segregation of frictional particles without cohesion.

Simulate an experimental test corresponding to the charge/discharge of a scale model batch hopper.

Hydrogeologic and Geochemistry Support for Open Pit and Underground Mining at Ernest Henry Mine (2015)

The Ernest Henry Mine is a large open pit copper mine with deeper mineralization that was targeted for underground mining. A Feasibility Study (FS) was conducted to evaluate the potential for mining of the underground component by sublevel‐caving methods.

Ore Pass Design - A Modeling Study (2015)

The LKAB mining company is currently carrying out investigations for a potential continued mining at depth in the Malmberget mine. Part of this work involves design of ore passes. The ore passes are a vital part of the transportation chain, and has, historically, been subject to extensive instabilities leading to closing and re-development of ore passes.

Chenab Railway Bridge Abutments (2015)

The Udhampur-Srinagar-Baramulla Rail Link (USBRL) project is a railway line linking the Kashmir Valley to the rest of India through the Himalayas. At 110 km long, this section consists of 88 km through tunnels and 11 km over bridges and viaducts. The Chenab River Bridge will be a concrete-filled truss steel arch bridge 359 m above the river valley, with a main span of 467 m and a total length of 1,315 m, making it the highest bridge deck and the seventh-longest spanning arch bridge in the world.

SKB Apsö UFM application (2015)

SKB asked ITASCA to apply an advanced modelling framework (UFM) on the Äspö site to estimate its consistency with structural and hydraulic data. The UFM modelling framework (detailed in Davy et al., (2010, 2013)) is used to assess fracturing parameters and improve the DFN models in Äspö using in‐depth data.