ROCK MECHANICAL ANALYSES FOR THE BOLIDEN DEEP REPOSITORY AT RÖNNSKÄR

Boliden AB is constructing an underground repository for final storage of process waste material from the Rönnskär copper smelter facility. The repository is excavated at a depth of 330 m and the main components are storage rooms with a vertical footprint of 16 by 18 m and with lengths varying between 50 and about 200 m. Itasca was contracted by Boliden to carry out rock mechanical analysis to assess the stability in both the short-and long-term (3000 years) perspectives. FLAC3D and 3DEC models were used to study global and local stability as well as the potential for long-term effects on flow paths in the rock mass resulting from the excavation of the repository.

Project Background

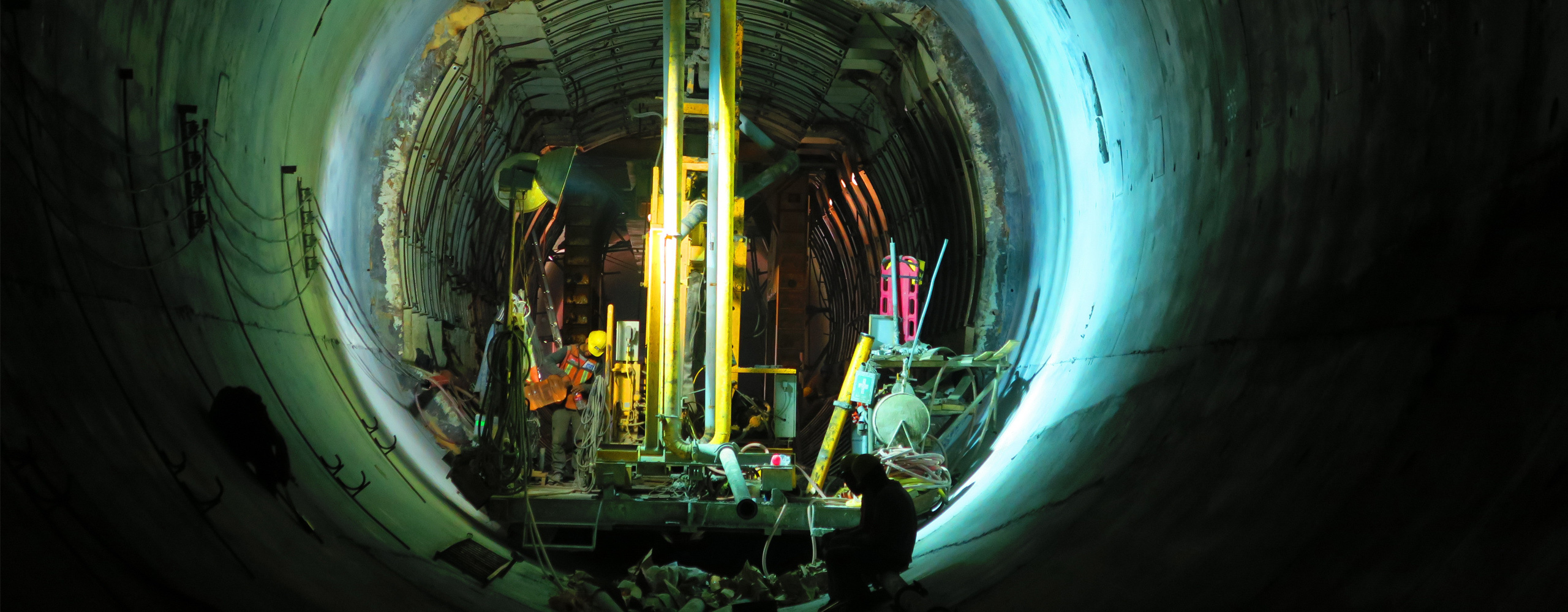

The Boliden AB mining company owns and operates six mines and five smelters, one of which is the Rönnskär copper smelter facility outside of Skellefteå, Sweden. The smelter facility separates commercial metals from waste material such as heavy metals (mercury, cadmium). To safely dispose of the process waste, Boliden is constructing a deep underground repository underneath the Rönnskär smelter at a depth of 330 m.

To satisfy geomechanical and hydrogeological regulatory and internal requirements, a number of rock mechanical analyses have been conducted by Itasca. The work has included stability analyses of the repository rooms, optimization of geometries, and long-term effect on flow paths. The latter is critical to the long-term function of the repository. The influence on flow pathways was judged with 3000 years as a reference time frame.

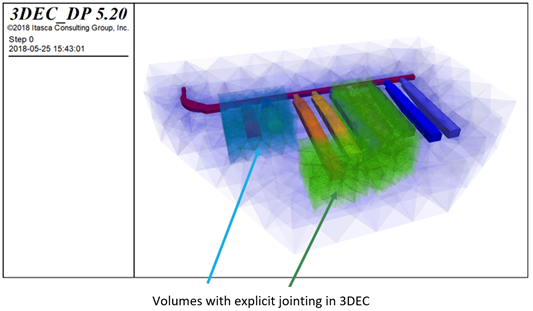

Global and local stability was evaluated using elasto-plastic analyses in FLAC3D while the long-term effects on flow-paths were considered via reducing strength parameters for joints simulated in 3DEC.

Model Description

The rock mass volume for the repository was chosen based on both the proximity to the smelter facility and the generally well-suited rock mass characteristics at the repository depths. The rock mass has a GSI value around 80, and cores indicate an RQD value over 90%. Rock mass geomechanical parameters were derived empirically using rock mass classification in conjunction with the Hoek-Brown failure criterion. Strength values for the linear Mohr-Coulomb criterion were obtained through curve-fitting to the curved Hoek Brown criterion. Joint strength values were determined from mapping during excavation of the ramp or approximated from values derived at facilities situated in similar rock conditions.

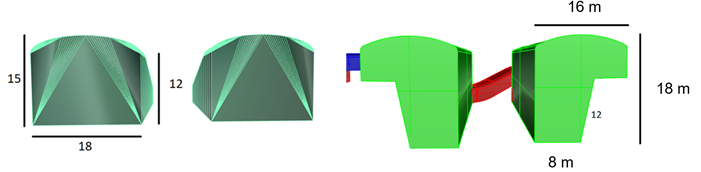

The layout of the repository rooms is shown in Figure 1, with an initial conceptual layout and a final production layout optimized for ease of depositing material and based on rock mechanics considerations.

Conceptual Analysis of Long-term Stability

Global stability and long-term effects were assessed based on the initial conceptual design using FLAC3D and 3DEC. Model geometry was generated utilizing the preprocessor and meshing tool Griddle. Stress and spalling analyses were performed in FLAC3D and the results were used to define areas of interest for explicit joint modeling in 3DEC, see Figure 2.

The long-term behavior was modeled by incrementally lowering the joint strength parameters around the excavations to simulate weathering and washout of fill material from joint surfaces. Long-term joint aperture and slip was compared with the initial (fresh excavation) state to estimate the potential long-term influence on flow paths through the rock mass.

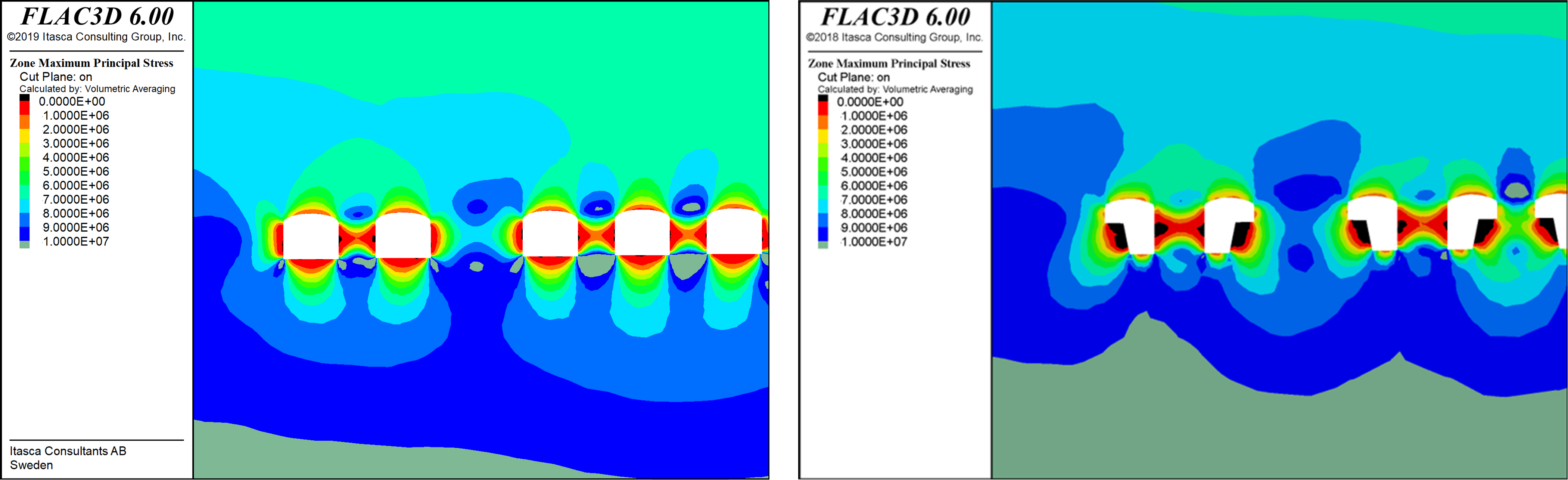

Verification of Production Layout

To facilitate efficient depositing of material, the rooms were redesigned to incorporate a raised shelf/bench from which material can be dumped from trucks. Stress analysis in FLAC3D was performed to optimize room dimensions adhering to operational needs without compromising the rock mechanical advantages of the conceptual design with regard to overall stability and long-term flow path influences.

The main rock mechanical concern for the production layout was to ensure compressive stresses through the pillars between the different rooms in order to prevent fracture opening (with potential for increased flow) between the rooms. The final design indicated the potential for wedge failures in the shelf due to significant destressing of the shelf corner (see Figure 3). This issue was addressed by specific staged pre-reinforcement using long bolts.

Measurement and Follow-up

The numerical modeling results were used to determine optimum measurement locations and alarm limits for deformation monitoring. A monitoring program with borehole extensometers was put in place to verify the geomechanical model and numerical analysis results, as well as to ensure a controlled and safe working environment.

Summary

For this project, Itasca used a combination of continuum and discontinuum models to evaluate global and local stability as well as long-term effects on flow paths for a one-of-a-kind facility. The models were able to demonstrate that the potential for increased flow in the rock mass due to the excavation of the repository over a time period of 3000 years is negligible. The models also demonstrated that there would be no measurable surface influence. An optimized production layout was also delivered from the project work.

Excavation of the facility began in 2019 (the ramp was excavated in 2017), and by mid-2020, six of the planned storage rooms were under excavation. The in-place measurement program shows (thus far) expected deformation behavior during excavation, thus validating both the geomechanical model and the numerical modeling results.