Jet Grouting Wall with Anchors

Project Description

Keller Group constructed a 13 m deep underground parking lot. After many trials utilizing concrete diaphragm panels for ground support, this approach was found to be impractical. This was mainly due to the high aggregate-size variability of the morainic deposit (unconsolidated glacial debris) at the site. In such complex geotechnical situations jet grouting offers a valid alternative to traditional support systems.

Jet grouting uses a small diameter perforation and is much more flexible. Injected cement consolidates the deposit materials in place with strength comparable to lean concrete. A wall with an equivalent thickness of 1.5 m was created and then supported with pre-stressed anchors. The embedment length of the wall below the excavation base was approximately 1.5 m.

Itasca's Role

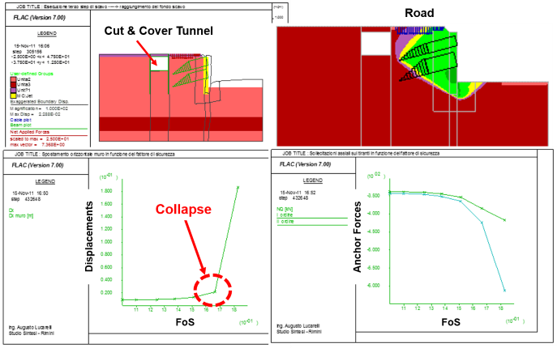

Our role was to introduce this unconventional system to the owner and perform the numerical analyses of the support system to ensure performance and stability. A special focus of the analysis was the stress state inside the jet wall, which was modeled as zones, as this is required to produce stress resultants and standard structural checks required by the building code. Ground displacements were also a major concern due to close proximity of existing buildings and roadways to the excavation.

The jet grouting was modeled as a Mohr coulomb constitutive material with cohesion calibrated from Uniaxial Compressive Strength (UCS) tests, assuming zero tensile strength. The constitutive model for the soil was calibrated using SPT tests and shear wave velocity measurement.

This work performed by Augusto Lucarelli, Principal Engineer, prior to employment with Itasca Consulting Group, Inc.

Project Results

The retaining wall was modeled using FLAC and was built within a morainic deposit. This allowed for a detailed evaluation of the stress inside the jet, load on anchors, and the safety factor (FoS) using a strength reduction approach. A global stability analysis was also conducted using a strength reduction procedure.

Monitoring data during construction has shown an excellent performance of the system without any significant ground movement around the excavation.

Project Image(s)