Depressurizing an Underground Ore Body at the McArthur River Mine in Northern Saskatchewan, Canada

Project Description

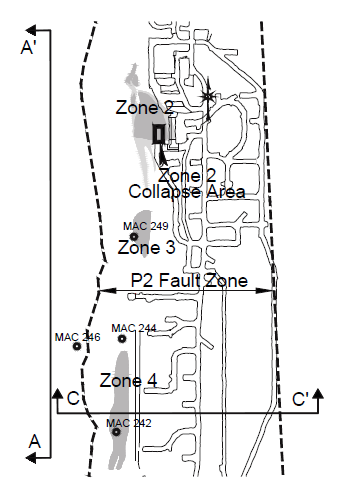

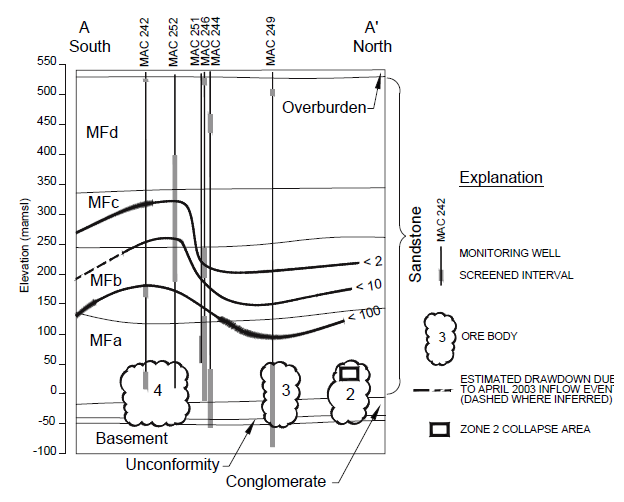

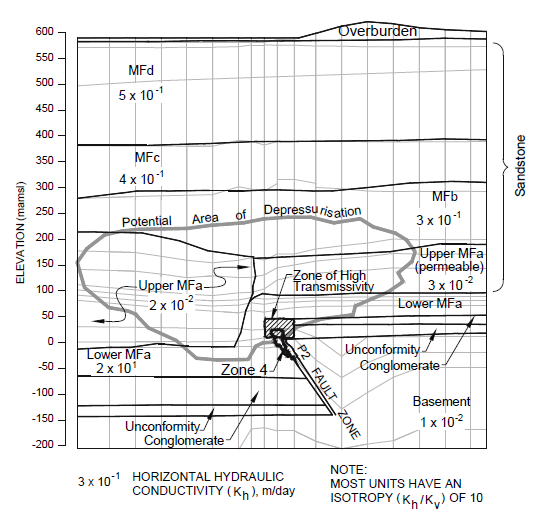

Pre‐mining depressurizing of a deep ore body at the McArthur River mine, the largest single producer of uranium in the world, was considered to decrease the risk associated with mining and increase the ground stability and the amount of ore that could be extracted. The challenge was to depressurize the high‐grade ore bodies without propagating a significant amount of drawdown to the surface where impacts on surface‐water resources and the associated aquatic habitat would be significant environmental issues. The objective was to evaluate the technical and economic feasibility of depressurizing the ore body.

Itasca's Role

Based on a limited amount of field data, a three‐dimensional finite‐element groundwater flow model was developed using MINEDW. Both steady‐state and transient calibrations of the groundwater flow model were conducted. The measured groundwater levels in 1992 were replicated in the steady‐state calibration. Subsequently, two transient calibrations were conducted, first to inflow from shafts and mine workings and then to the inflow rates and water levels following the unexpected April 2003 major inflow event. Lastly, predictive simulations were made with the calibrated model.

Project Results

The prediction results were used to determine the amount of water that would have to be pumped from surface wells or extracted with underground drainholes to meet the depressuriziation goal, the associated magnitude and extent of drawdown that would propogate to the surface over the life of the operation, as well as its impact on surface‐water resources. In addition, the results were used to design a prototype depressurizing well and a 30‐day pumping test.

Project Image(s)

References

Liu, H., J. Hatley, R. Bashir, and L. C. Atkinson. 2008. Depressurising an Underground Ore Body at the McArthur River Mine in Northern Saskatchewan, Canada. Proceedings, 10th International Mine Water Association Congress Karlovy Vary, Czech Republic, June), Paper No. 206. Ostrava: VSB ‐Technical University of Ostrava.