Mechanical testing of a model baked anode material with PFC

Project Description

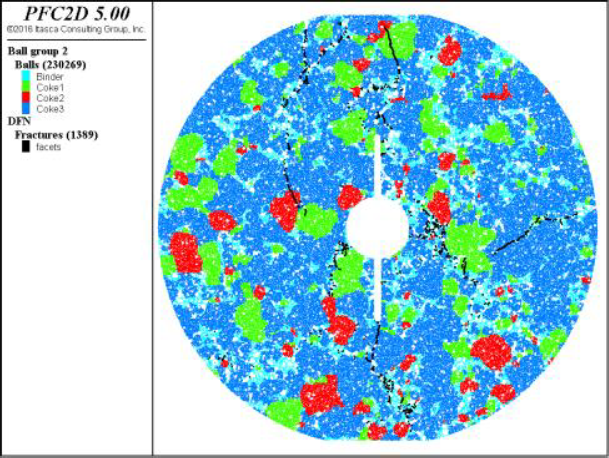

A baked anode is a complex material, that results from the mixing and baking of different petrol coke grains, with different size distributions, with a pitch. A preliminary study (ICSAS16-CST-MFG-35143-01) developed a PFC2D model accounting for the microstructure of a baked anode, using the Bonded Particle Model (BPM).

The new goals are to: 1) improve the geometrical description of the baked anode material, and 2) setup procedures simplifying the application of a mechanical load on the model material, and comparing its mechanical response with experimental data.

Itasca's Role

Improve the previously developed PFC2D environment by integrating more realistic size distributions of the grains, pore content, and binder distribution, as well as “open porosity”.

Implement shape factor measurements (aspect ratio, sphericity, roundness, convexity, compactness) on the reconstructed particles and compare results with real structure.

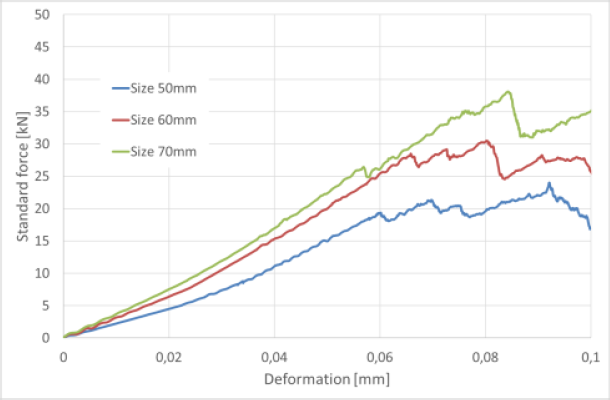

Calibrate intact BPM matrix then setup an axial loading test of a disk-shaped specimen with a pre-engineered notch (see figure). Characterize the repeatability of the measurements and the influence of specimen size. Study the influence of a notch, of the Young modulus, and of the binder strength.

Project Results

A parameterized environment is available, that simulates the mechanical loading of a disk-shaped specimen with a preengineered notch.

The geometrical description of the material now includes ”real” grain size distributions, new volume fractions for grains and pores, and “open porosity”.

Use of this model confirms that the elastic slope, crack pattern and peak force are highly dependant on the geometrical repartition and on the distribution of voids and pores, while the specimen size has a strong influence on the linear slope and on the peak force.

Project Image(s)